Plant Optimisation

Wastewater treatment plant optimisation is one of the most unrecognised assets in the operation of a wastewater treatment plant, yet it can represent the single biggest opportunity for performance improvement and reducing operating costs.

Hydroflux® engineers have experience in most industry sectors and will work though your processes systematically to achieve the best results for your wastewater treatment plant.

Industries we assist:

Hydroflux Utilities have assisted many different types and sizes of businesses to optimise their wastewater treatment processes and have expertise in virtually all physical chemical, aerobic and anaerobic biological plants and sludge handling equipment.

Specialty industry sectors include:

- Food and Beverage

- Construction

- Mining

- Manufacturing

- Power

Types of optimisation programs and costs.

- Chemical

One of the most popular programs is the chemical evaluation. It is extremely rare that clients do not reduce the operational costs of the plant immediately following the assessment.

- Equipment optimisation.

We will review all the individual components in the plant and verify that the existing equipment is being used to its fullest potential by examining operating data and performance.

- Operating procedures. We will review the current standard operating procedures and discuss these with all operators as we often find operators have developed niche improvements themselves that are not always suitably shared. Once the best mode of operation has been established, Hydroflux can provide operational matrixes, flow charts or update the manuals as preferred. Comprehensive training sessions can also be supplied to ensure consistency of operation across the shifts.

Costs

The costs for optimisation programs depend on the level and intensity of the program but Hydroflux Utilities will always make an initial assessment free of charge.

Please contact our teams on:

09 352 2052

[email protected]

Hydroflux Utilities offer many different types of programs and reports to suit a range of processes and budgets. Please see below for a brief overview.

When operating a physical chemical treatment plant such as a DAF or clarifier, the performance of the plant is highly dependent on the chemical program used and the respective dose rates. Generally speaking, the more chemicals you add, the better the treated water quality is but there is always a point of diminishing return.

An example of what we can achieve is below:

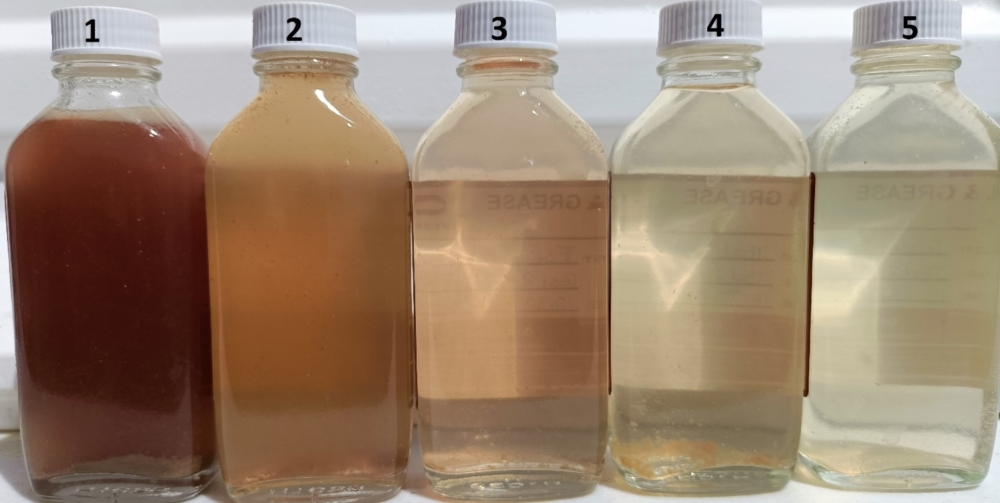

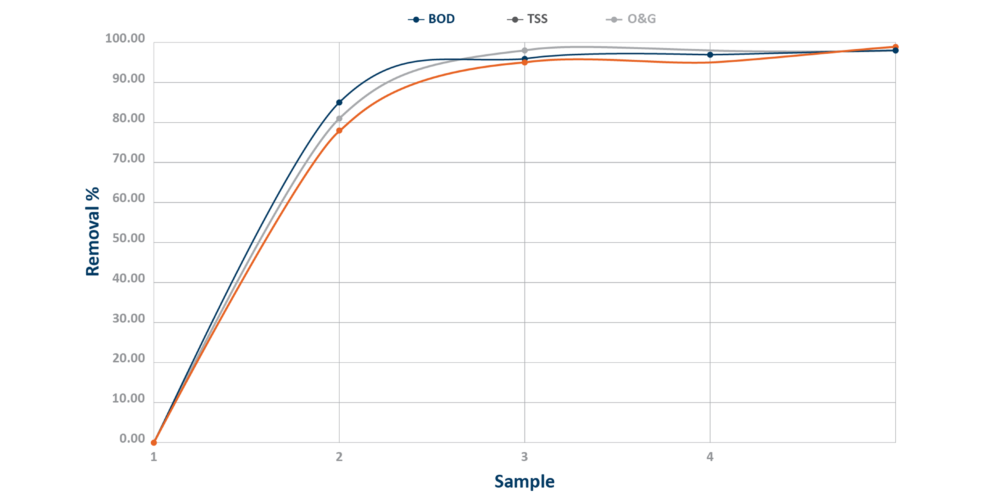

Sample 1 is the raw pre-treated sample, sample 2-5 show an increasing spend on chemicals to improve the DAF effluent water quality, all of which meet sites discharge requirements.

Visually the difference in water quality is quite large between the samples, and we can see a clear improvement in water quality as we continue to increase chemical spend. However, when we review the removal efficiency of common analytes BOD/TSS, we do not see an equal improvement (see chart). The testing found that we hit a meaningful peak between samples 2&3, any further increase in chemical spend to remove the remaining contaminants and colour will look good but have minimal to no impact on chargeable pollutants BOD or TSS.

More interestingly, when we review the total cost of treatment ($/kL) sample 2 comes out as the most economical option. Whilst this program has the highest trade waste pollutant charge, it provides significantly lower chemical and sludge disposal charges. The difference in these charges between sample 2 and 3 is $0.15/kL which resulted in $100k/annum savings for this site.

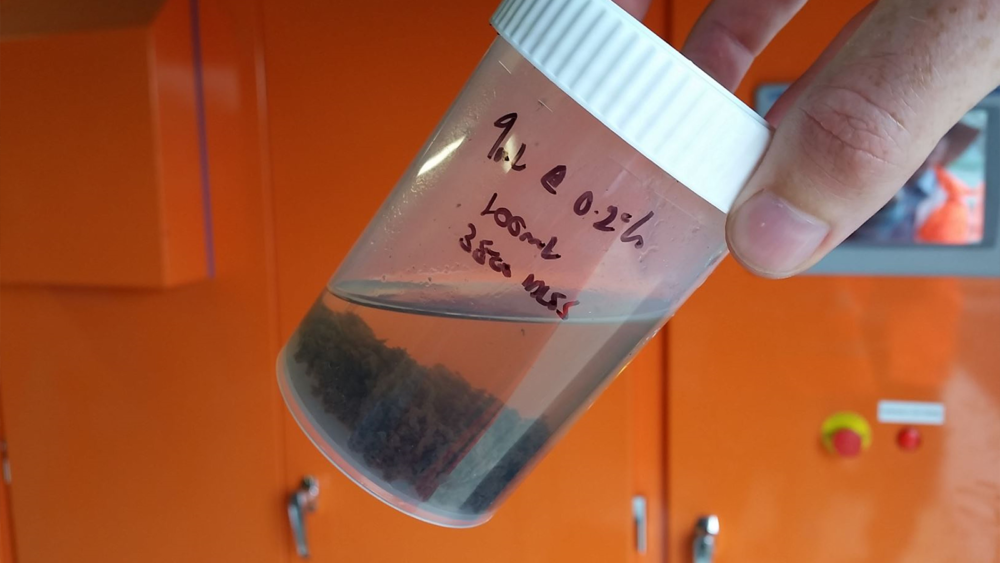

There can be a number of reasons to consider outsourcing the optimisation of your biological treatment plant. In industrial wastewater, some of the most common reasons include:

- Increases in volume due to growth or the addition of new products

- Changes in raw materials used in the processing plant

- The desire or need to implement energy saving measures

- Lack of operating resources

- Failure or aging of equipment

Biological processes are complex and there are never two plants the same, particularly in industrial wastewater applications.

The solution

Hydroflux Utilities use a proven staged process when engaged for biological plant optimisation. This can be a relatively extensive process but always produces results.

The costs for optimisation programs depend on the level and intensity of the program but Hydroflux Utilities will always make an initial assessment free of charge.

With sludge disposal costs increasing year on year and regulators becoming far more stringent on the types of waste they receive, it may be time to review your sludge handling process.

Hydroflux utilities have expertise in the design and operation of all types of sludge handling, thickening, dewatering and drying systems and it is rare that a sludge handling optimisation study conducted on an industrial site does not reap rewards.

Whether it involves primary or secondary sludge, a typical sludge handling optimisation study will involve one or a number of the following steps

- Review of the overall sludge handling process

- Detailed chemical review

- Analysis and review of disposal routes considering dryness and constitution

- Equipment assessment and recommendations

Hydroflux Utilities has a range of sludge dewatering equipment available for trial or hire.

The costs for optimisation programs depend on the level and intensity of the program but Hydroflux Utilities will always make an initial assessment free of charge.